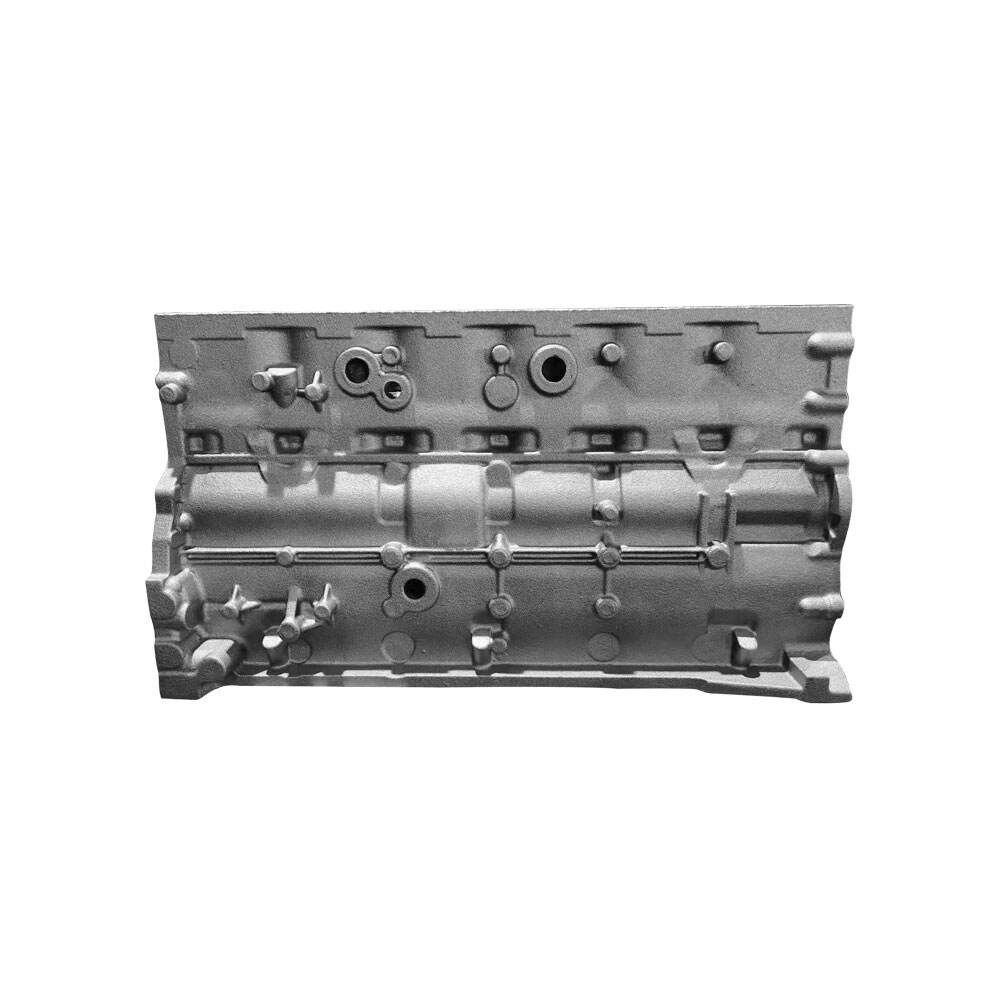

metal 3d printing process

Metal 3D printing, also known as additive manufacturing, represents a revolutionary approach to manufacturing metal components. This process builds objects layer by layer using metal powder or wire feedstock, guided by digital 3D models. The technology employs various methods, including Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). During the process, high-powered lasers or electron beams selectively melt and fuse metal particles together, creating complex geometries that would be impossible or extremely costly to produce through traditional manufacturing methods. The process begins with a detailed CAD model, which is sliced into thin layers by specialized software. Each layer is then systematically built up, with the laser or beam precisely melting the metal material according to the design specifications. This technology enables the creation of intricate internal structures, optimized topologies, and consolidated parts that traditionally would require multiple components and assembly steps. The process accommodates a wide range of metals, including titanium, aluminum, stainless steel, and various superalloys, making it suitable for aerospace, medical, automotive, and industrial applications. The technology's precision and ability to create complex geometries have revolutionized prototyping and production processes across multiple industries.