aluminum casting factory

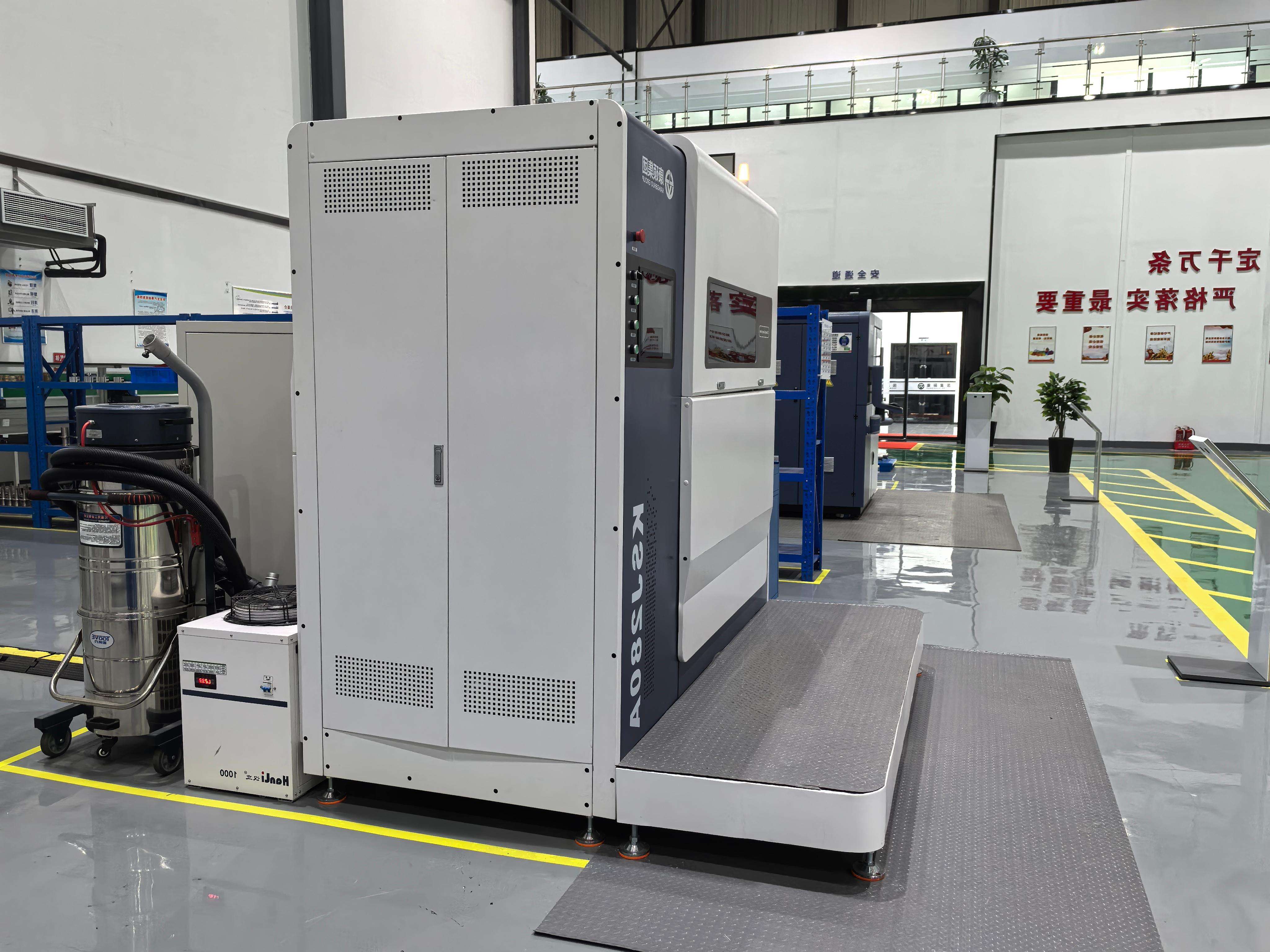

An aluminum casting factory represents a state-of-the-art manufacturing facility dedicated to transforming molten aluminum into precise, high-quality components. These facilities utilize advanced casting technologies, including die casting, permanent mold casting, and sand casting processes, to create a wide range of products for various industries. The factory employs sophisticated temperature control systems, automated pouring mechanisms, and precision mold designs to ensure consistent product quality. Modern aluminum casting facilities feature computer-controlled production lines that monitor and adjust casting parameters in real-time, maintaining optimal production conditions. Quality control stations equipped with advanced testing equipment, including X-ray inspection and spectrometric analysis tools, verify the structural integrity and composition of each cast component. The facility's capabilities extend to producing both simple and complex geometries, with sizes ranging from small electronic components to large automotive parts. Environmental control systems manage dust collection, metal recovery, and waste reduction, ensuring sustainable operations while maintaining high production efficiency. The factory's layout typically includes dedicated areas for pattern making, core production, melting operations, casting, heat treatment, and finishing processes, all working in synchronized coordination to deliver superior aluminum castings.