H-1 Factory Building, Mingshan Industrial Park, Gaoping Economic and Technological Development Zone, Jincheng City, Shanxi Province, China. +86-15921818960 [email protected]

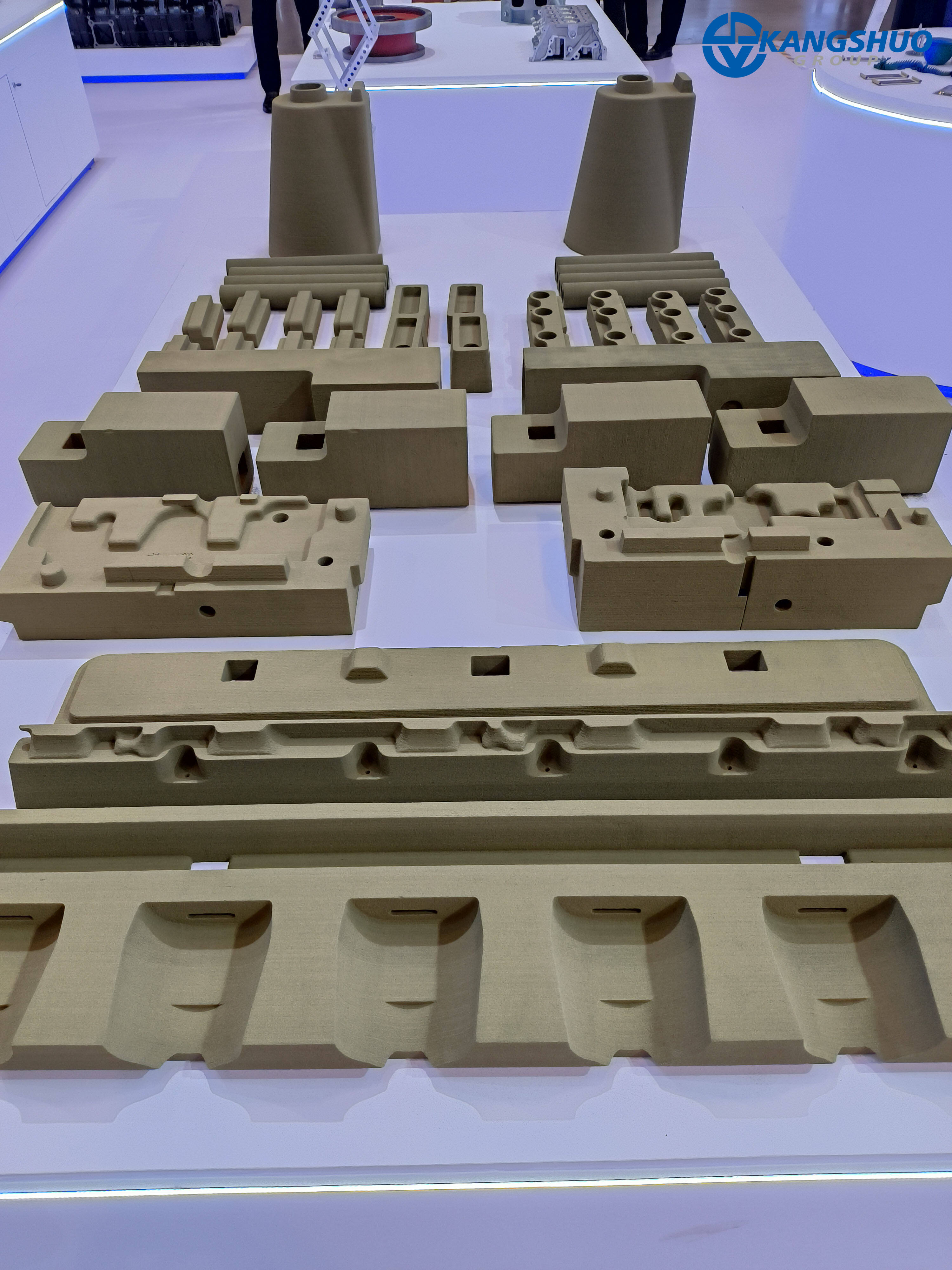

In the rapidly evolving field of additive manufacturing, sand‐based 3D printing is gaining traction for applications spanning from foundry molds to architectural prototypes. However, not all sands are created equal—different use cases demand tailored selection to optimize performance, cost, and reliability.

Why it matters:

Permeability & Gas Evolution: High permeability sands reduce defects such as blowholes. A study by the American Foundry Society reports that sands with a permeability (as measured by Preece method) above 400 Darcy significantly reduced casting porosity by 35% (American Foundry Society, 2023).

Thermal Behavior: Sands with lower thermal expansion coefficients (e.g., 6 × 10^–6 /°C) minimize mold cracking during pour.

Recommended sand type: Gaussian, rounded silica sand with a controlled grain size distribution (typically 100–200 microns) and low thermal expansion.

Key criteria:

Surface Finish & Detail Resolution: Medium‐grade silica with finer particle sizes (around 50–100 microns) supports fine detail replication. ISO 2520 standard shows that printing resolution improves by up to 22% when average grain size drops from 200 to 80 microns (ISO, 2022).

Binding Efficiency: Finer sands increase binder contact surface area, enhancing cure strength—reported improvements in green part tensile strength of 18–25% (BinderTech Journal, 2024).

Recommended sand type: Fine, well‐graded silica or zircon sand, enabling sharp edges and delicate features.

Performance needs:

Mechanical Strength & Stability: Silica–zircon blends or high‐strength synthetic sands achieve compressive strength over 30 MPa in printed cores, compared to 20 MPa with standard silica (Additive Manufacturing Review, 2024).

Dimensional Accuracy: Controlled sphericity with low fines improves dimensional tolerance to below ±0.3 mm on ±100 mm parts.

Recommended sand type: High‐roundness silica or silica–zircon composite, carefully graded to balance strength and print fidelity.

| Application Area | Critical Properties | Typical Grain Size | Recommended Sand Type |

|---|---|---|---|

| Metal Casting / Foundry | Permeability, thermal expansion, strength | 100–200 µm | Rounded silica with controlled gradation |

| Architectural Prototypes | Resolution, surface smoothness | 50–100 µm | Fine silica or zircon |

| Functional Prototypes | Mechanical strength, accuracy | Similar to above, graded | Synthetic silica or silica–zircon blends |

Data Sources:

American Foundry Society (2023), Impact of Sand Permeability on Casting Defects

ISO (2022), ISO 2520: Evaluation of Grain Size Effect in 3D Sand Printing

BinderTech Journal (2024), Binder-Sand Interaction and Green Strength in Additive Manufacture

Additive Manufacturing Review (2024), Performance Metrics of Composite Sands in Structural Models

By aligning sand choice with the functional priorities of the application—whether permeability, resolution, or strength—manufacturers and designers can ensure optimal performance for their printed parts. For more in-depth data, guidelines, or assistance in sand selection, feel free to contact our technical team.