aluminum casting near me

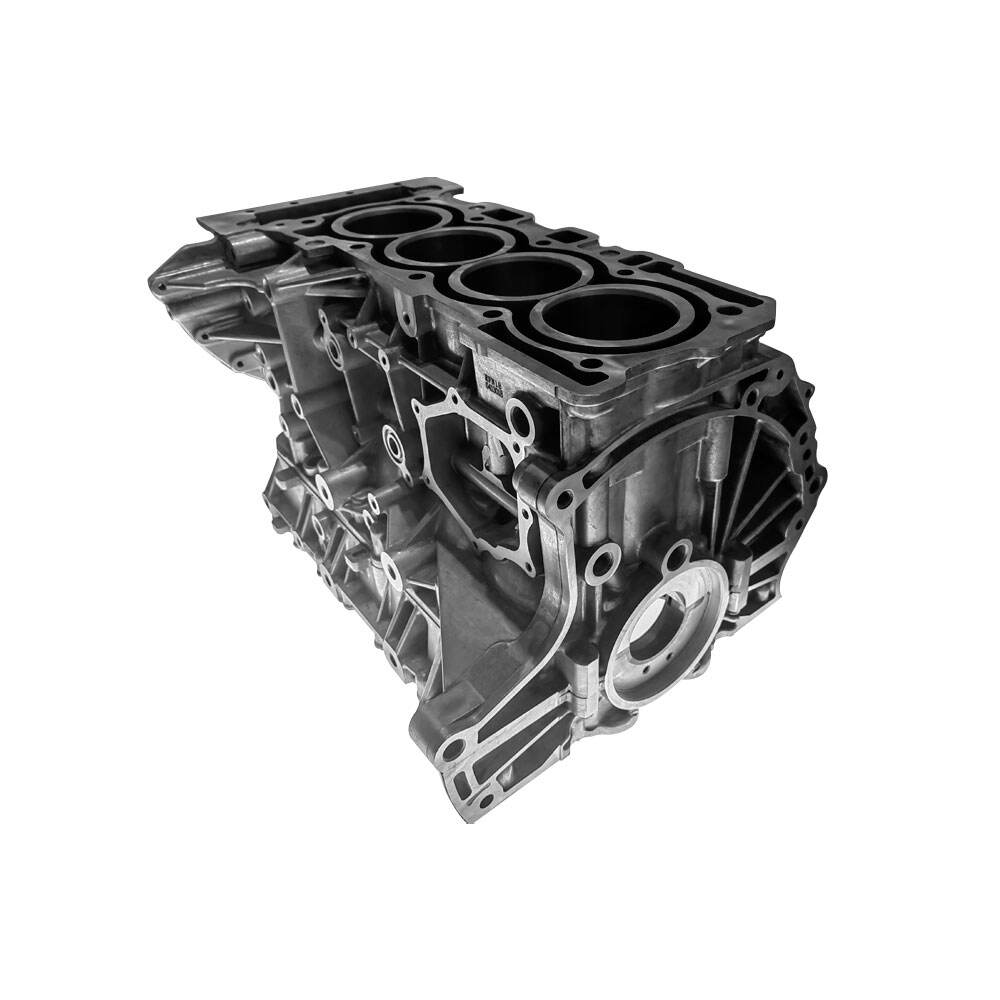

Aluminum casting services in your local area provide essential manufacturing solutions for businesses and individuals seeking high-quality metal components. These facilities utilize state-of-the-art foundry equipment and advanced casting techniques to transform molten aluminum into precise, durable parts. The process encompasses various methods including die casting, sand casting, and permanent mold casting, each suited to different production requirements and specifications. Local aluminum casting facilities offer the advantage of quick turnaround times, direct communication, and reduced shipping costs. They typically provide comprehensive services from design assistance and pattern making to final machining and surface finishing. These foundries can produce components ranging from small intricate parts to large industrial pieces, serving industries such as automotive, aerospace, construction, and consumer goods manufacturing. Modern aluminum casting facilities employ computer-aided design and simulation software to optimize mold filling and solidification, ensuring consistent quality and minimal defects. They also implement strict quality control measures, including material testing and dimensional verification, to meet industry standards and customer specifications.