aluminum die casting manufacturer

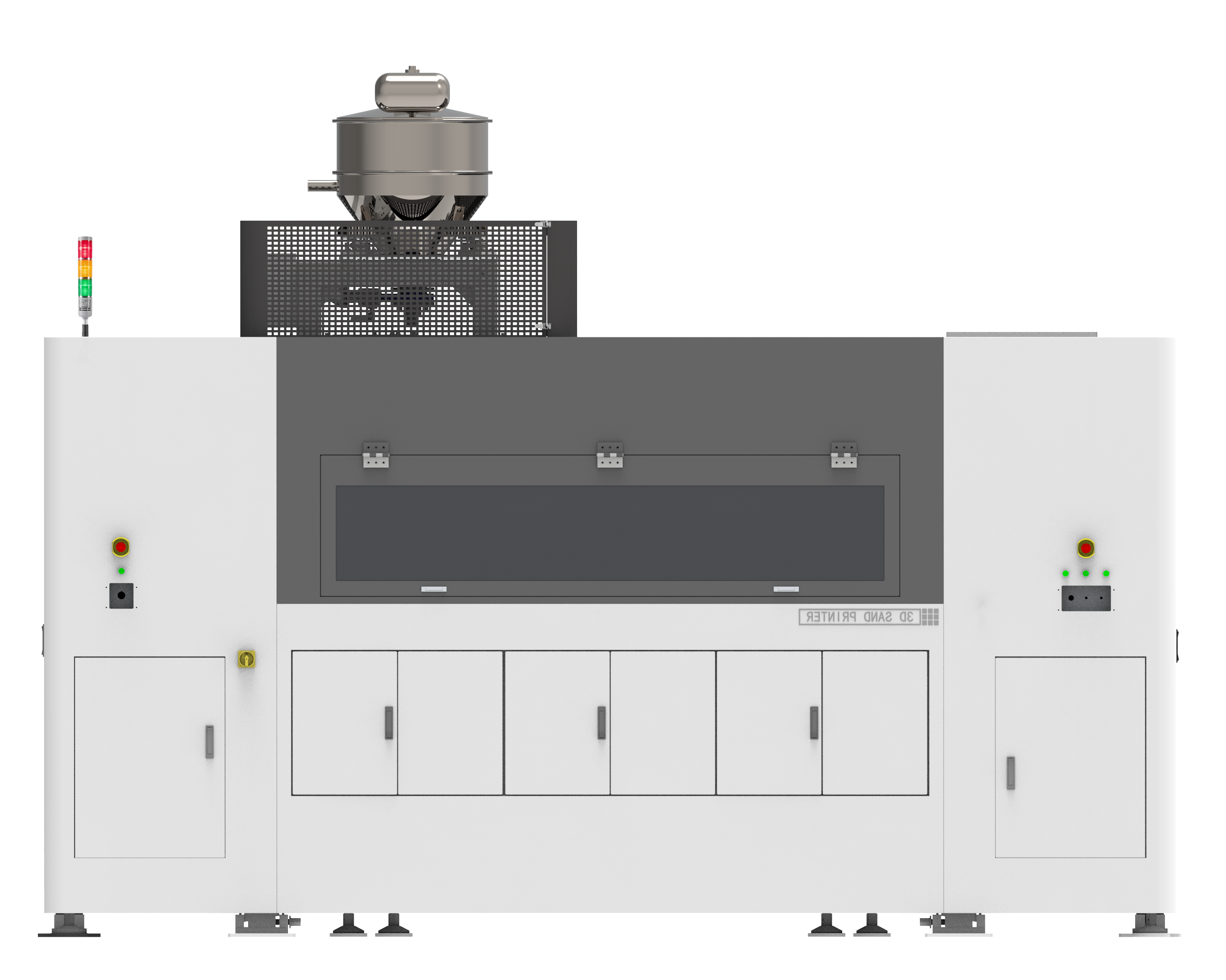

An aluminum die casting manufacturer represents a cornerstone of modern industrial production, specializing in creating precise, durable metal components through an advanced casting process. These facilities combine cutting-edge technology with metallurgical expertise to transform molten aluminum into complex parts with exceptional accuracy. The manufacturing process utilizes sophisticated high-pressure die casting machines, capable of producing components with intricate geometries and tight tolerances. State-of-the-art facilities typically feature automated production lines, advanced quality control systems, and comprehensive testing equipment to ensure consistent product quality. The manufacturer's capabilities extend to various industries, including automotive, aerospace, electronics, and consumer goods, providing solutions for both high-volume production runs and specialized custom projects. Modern aluminum die casting facilities implement computer-aided design and simulation software to optimize mold design and casting parameters, resulting in superior product quality and reduced development time. The manufacturer's expertise encompasses the entire production cycle, from initial design consultation and prototype development to final finishing and assembly operations. These facilities maintain strict quality control measures, often holding ISO certifications and implementing statistical process control methods to ensure consistent product quality.