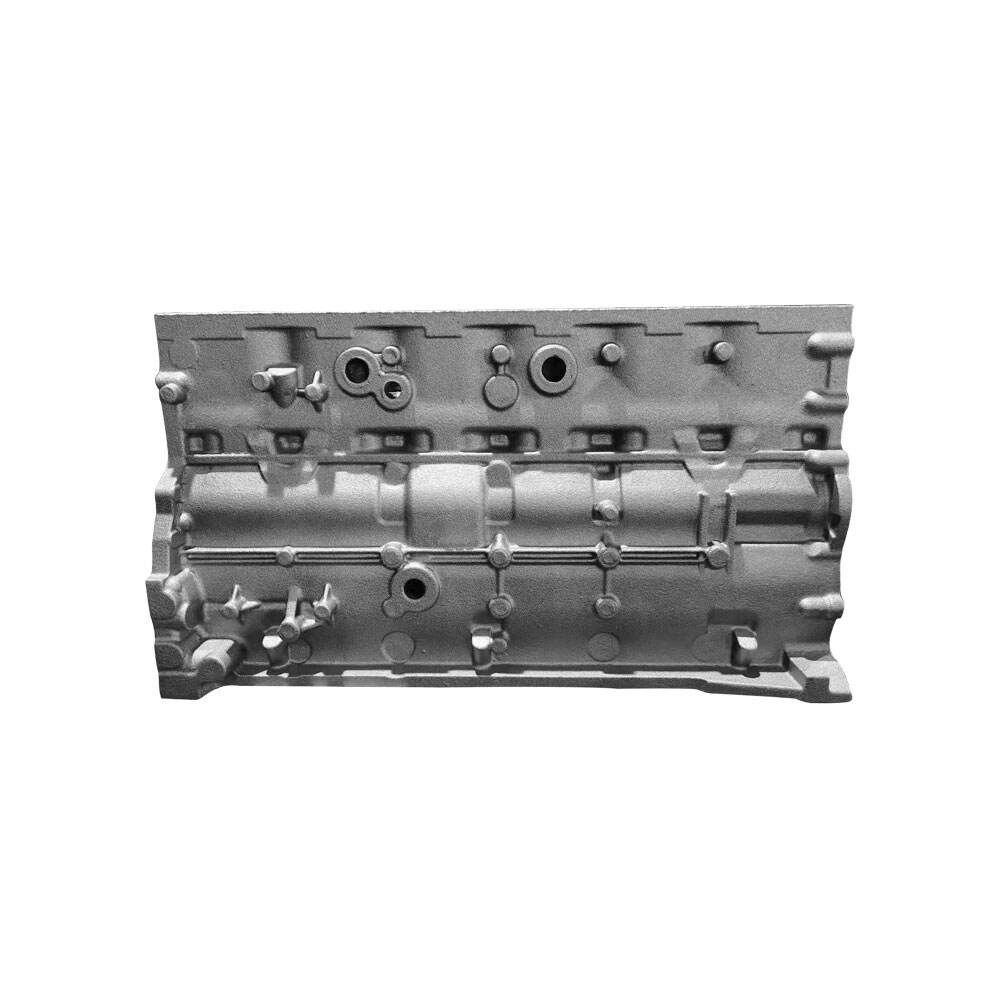

aluminium casting near me

Aluminum casting services near you provide essential manufacturing solutions for businesses and individuals seeking high-quality metal components. These local foundries specialize in transforming molten aluminum into precise, durable parts through various casting methods, including die casting, sand casting, and permanent mold casting. Modern aluminum casting facilities employ advanced technology and automated processes to ensure consistent quality and dimensional accuracy. The proximity of local casting services offers numerous advantages, including reduced shipping costs, faster turnaround times, and improved communication throughout the manufacturing process. These facilities typically handle both small and large production runs, serving industries such as automotive, aerospace, construction, and consumer goods manufacturing. The casting process begins with creating detailed molds based on customer specifications, followed by melting high-grade aluminum alloys under controlled conditions. The molten metal is then poured into the molds, allowed to solidify, and undergone post-processing treatments such as heat treating, machining, or surface finishing. Local foundries often provide additional services like design consultation, prototype development, and quality testing to ensure components meet specific requirements.