H-1 Factory Building, Mingshan Industrial Park, Gaoping Economic and Technological Development Zone, Jincheng City, Shanxi Province, China. +86-15921818960 [email protected]

Ever spent over $65,000 building a prototype mold—only to scrap it after multiple failed iterations?

You're not alone.

A European auto parts manufacturer recently spent that amount on traditional pattern and tooling just to test a new part design. After two rounds of rework, the mold still didn’t meet requirements. The project was shelved, and so were the profits.

Now imagine if they had used 3D sand printing instead.

Traditional mold-making requires time-consuming fabrication of wood or aluminum patterns, followed by tooling. It can take weeks (even months) and tens of thousands of dollars.

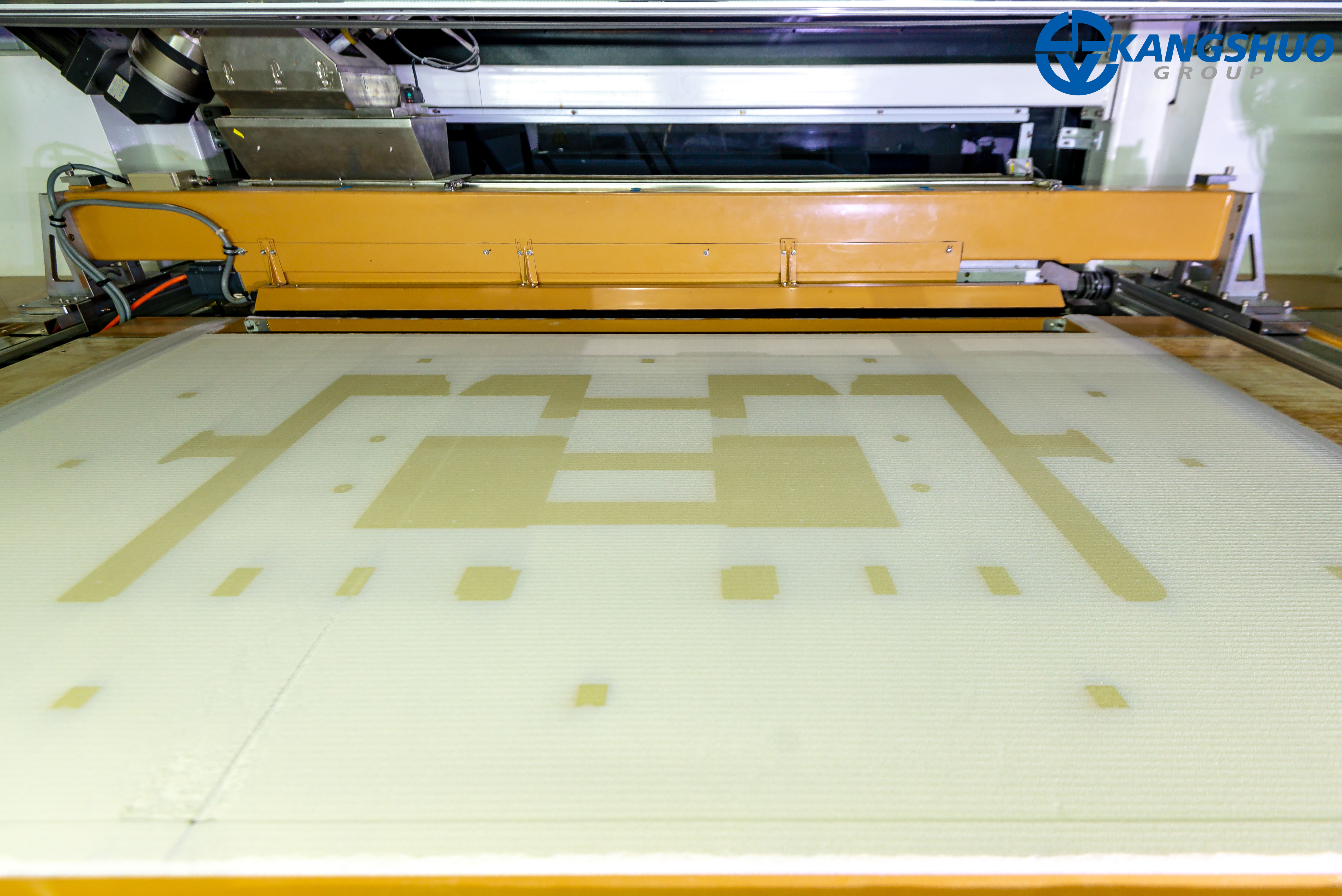

3D sand printing eliminates that entirely.

With just a CAD file, complex cores and molds can be printed directly, with no pattern, no tooling, and no manual assembly. The total cost? As low as:

CAD data processing: $0–$200

Materials & printing services: ~$990

Post-processing & finishing: $550–$1,100

Total estimate: $1,500–$2,300

That’s over 95% less than the cost of traditional methods.

| Item | Traditional Mold | 3D Sand Printing |

|---|---|---|

| Pattern & Tooling | $65,000 | $0 |

| Materials & Printing | — | ~$990 |

| Post-processing | — | $550–$1,100 |

| Estimated Total | $65,000 | $1,500–$2,300 |

Whether it’s thin walls, hollow channels, or multi-core structures, traditional core making involves manual gluing and assembly—raising the risk of alignment issues and scrap.

3D printing solves that by producing complex geometries in a single step, minimizing assembly, reducing error, and dramatically cutting scrap rates.

Studies show a 30–50% drop in rework and material waste for small-batch production of intricate cores.

Need a mold fast?

Traditional processes can take up to 6–8 weeks. With 3D sand printing, you can get the mold in 3–5 days—sometimes in as little as 72 hours.

That’s weeks of lead time converted into faster R&D, faster iteration, and faster product launch.

Let’s compare again:

Traditional failure:

Tooling: $65,000

Rework + scrap: $5,000+

Lead time: 6–8 weeks

3D sand printing success:

Printing + finishing: ~$2,000

Success on first try (85%+ probability)

Lead time: under a week

Savings: ~$63,000, plus weeks of valuable engineering time.

🚀 Prototype runs and design verification

🧩 Complex geometries that are hard to assemble with traditional cores

⏱ Tight timelines that can’t wait for tooling

🏭 Small-batch production without committing to full-scale molds

📦 No pattern storage needed — digital files mean zero physical inventory

We understand. Some teams worry about:

High cost of owning a 3D sand printer

Quality consistency

Unknowns in switching from traditional workflows

That’s why we offer printing-as-a-service.

No equipment investment, no long learning curve. Just send us your CAD files—we’ll handle the printing, post-processing, and even shipping.

You pay per project, and see the results before committing to anything long term.

Want to know if 3D sand printing will work for your part?

Send us your design and we’ll walk you through a cost breakdown—step by step. No commitments. No hard sell.

Just real-world numbers that speak for themselves.

📩 Contact us now for a free project evaluation.