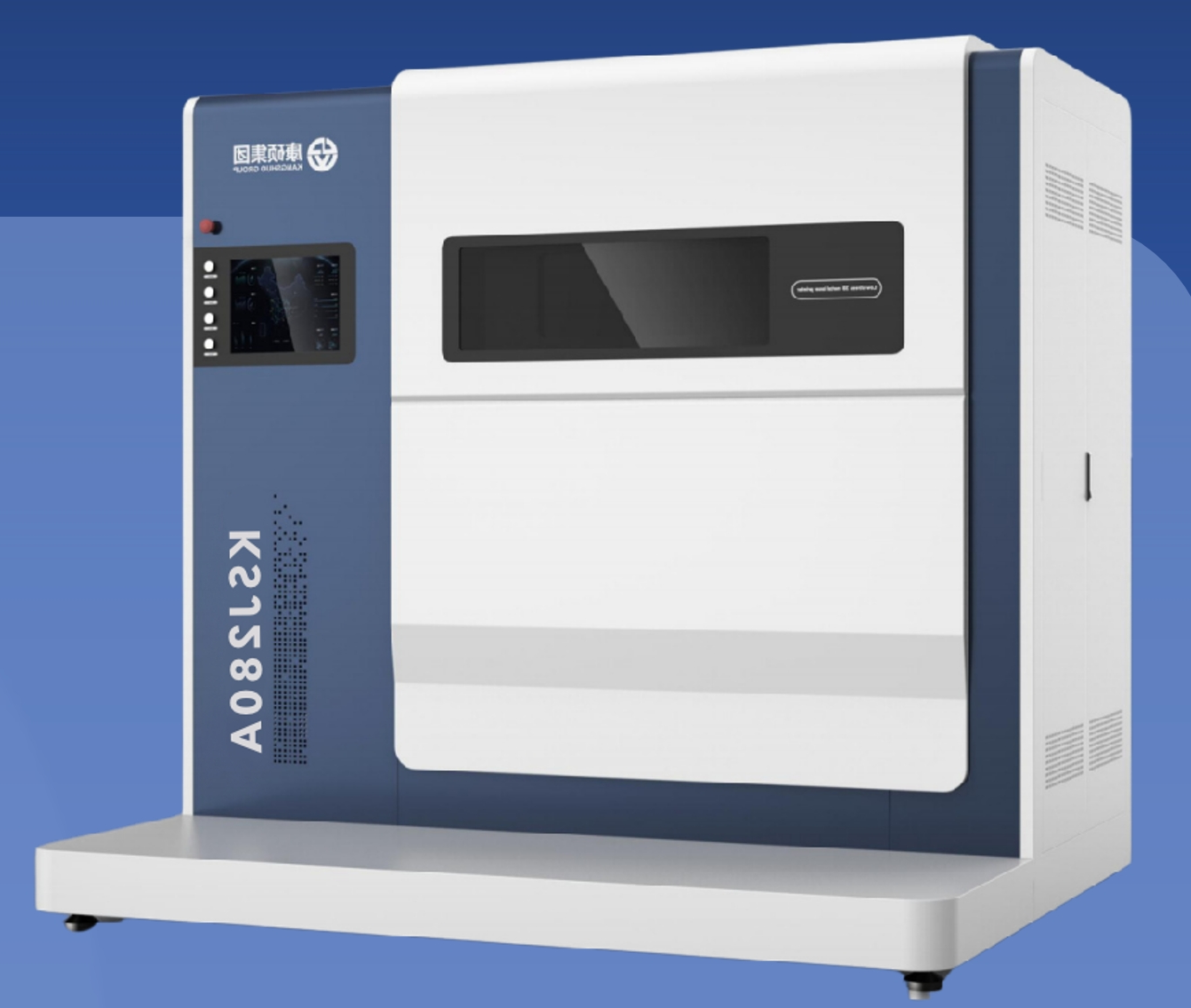

ceramic printer

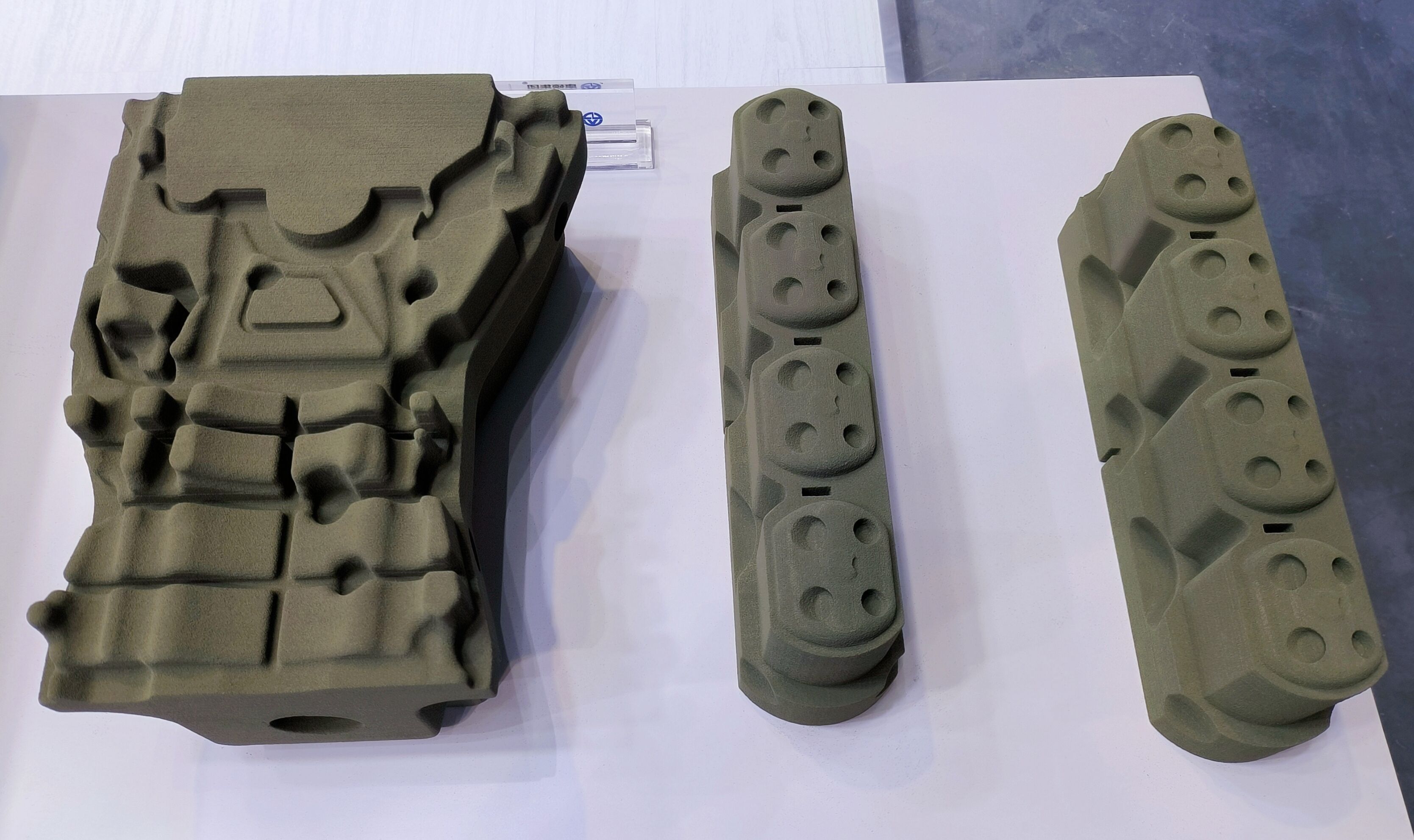

A ceramic printer represents a groundbreaking advancement in additive manufacturing technology, specifically designed to produce complex ceramic components with unprecedented precision and efficiency. This innovative device utilizes specialized ceramic slurry or paste materials to create three-dimensional objects layer by layer, offering exceptional detail and structural integrity. The printer operates through a sophisticated system that precisely controls material deposition, temperature, and curing processes to ensure optimal results. With the ability to handle various ceramic compositions, including alumina, zirconia, and porcelain, these printers can produce items ranging from intricate artistic pieces to functional industrial components. The technology incorporates advanced features such as multi-axis printing capabilities, automated material feeding systems, and precise temperature control mechanisms. These printers excel in maintaining consistent quality across production runs while significantly reducing material waste compared to traditional ceramic manufacturing methods. The system's integrated software allows for seamless translation of digital designs into physical objects, enabling both rapid prototyping and full-scale production capabilities. Modern ceramic printers also feature sophisticated monitoring systems that ensure print quality and maintain optimal printing conditions throughout the fabrication process.