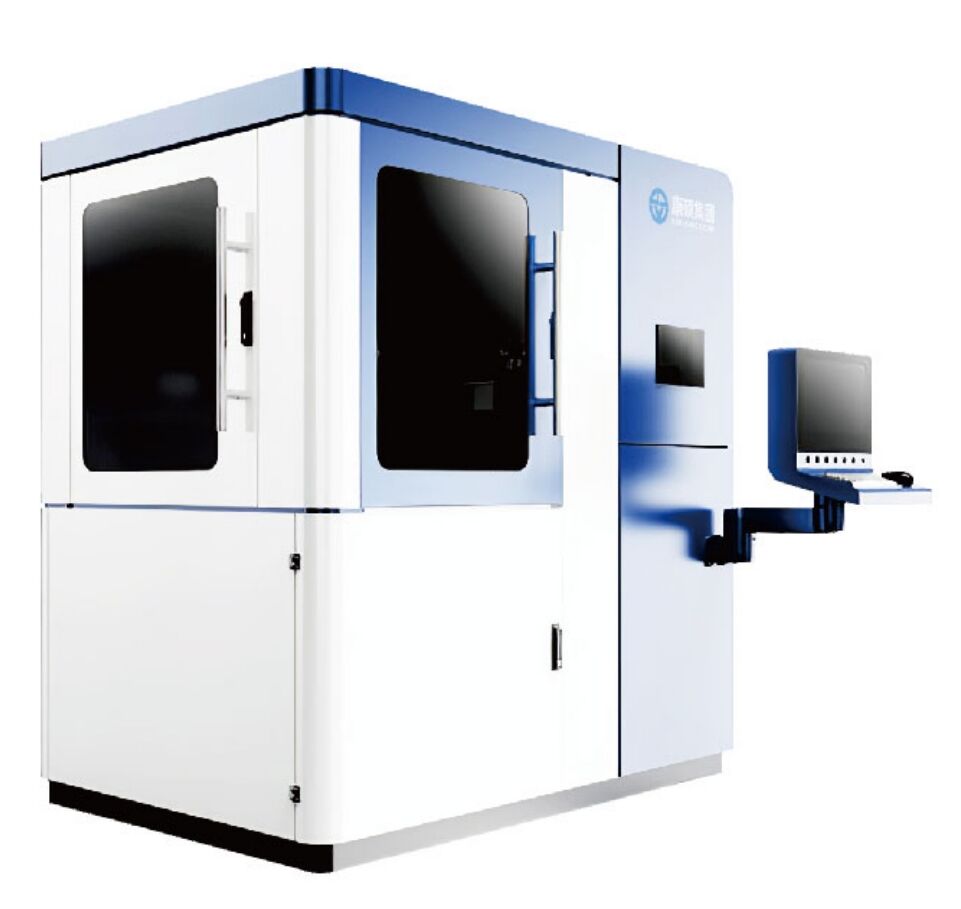

ceramic resin 3d printing

Ceramic resin 3D printing represents a groundbreaking advancement in additive manufacturing technology, combining the precision of stereolithography with the unique properties of ceramic materials. This innovative process uses specialized photosensitive resins containing ceramic particles, which are carefully layered and cured using UV light to create complex ceramic structures. The technology enables the production of highly detailed ceramic components with exceptional structural integrity and dimensional accuracy. During the printing process, the ceramic-loaded resin is systematically exposed to UV light, causing it to solidify layer by layer, ultimately forming the desired three-dimensional object. After printing, the components undergo a crucial post-processing phase involving debinding and sintering, where the organic binder is removed, and the ceramic particles are fused at high temperatures. This results in fully dense ceramic parts with outstanding mechanical, thermal, and chemical resistance properties. The technology finds extensive applications across various industries, including aerospace, medical devices, electronics, and artistic endeavors. It excels in producing intricate geometries that would be impossible or prohibitively expensive to manufacture using traditional ceramic processing methods.