ceramic 3d printer price

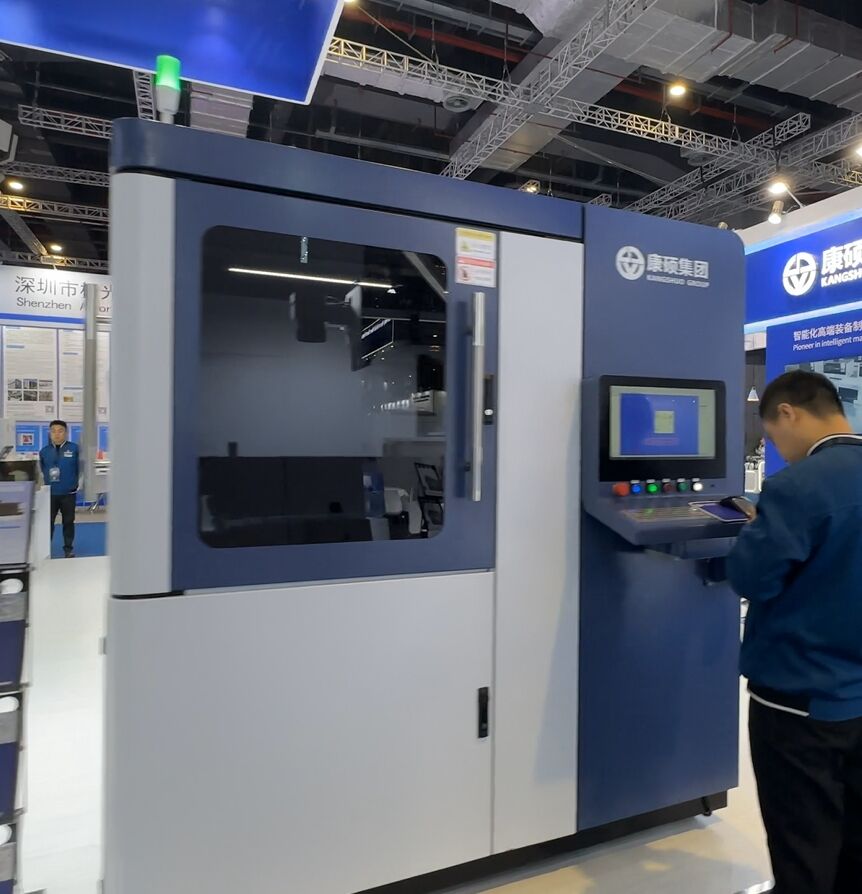

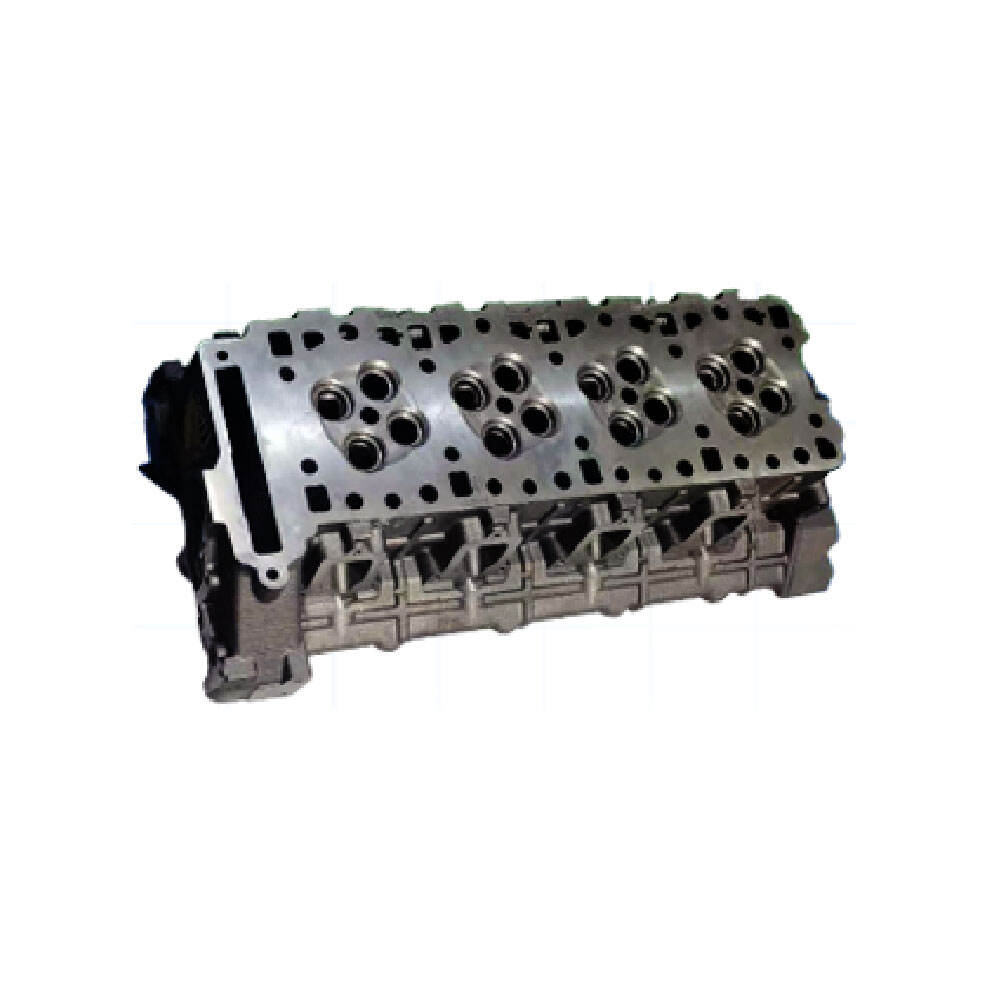

Ceramic 3D printer prices represent a significant investment consideration in modern manufacturing technology. These specialized machines, ranging from $3,000 for entry-level models to over $50,000 for industrial systems, offer unique capabilities in creating complex ceramic structures. The price variation reflects differences in build volume, precision, material compatibility, and automation features. Entry-level printers typically handle smaller projects with basic materials, while mid-range options ($15,000-$30,000) provide enhanced precision and material versatility. Professional and industrial printers at the higher end of the price spectrum offer advanced features like automated material handling, larger build volumes, and superior resolution capabilities. The price also encompasses essential accessories, software licenses, and initial setup costs. Most manufacturers provide comprehensive packages including training, warranty coverage, and technical support. The total investment consideration should account for ongoing operational costs, including materials, maintenance, and potential upgrades. The market shows a trend toward more affordable options as technology advances, making ceramic 3D printing increasingly accessible to smaller businesses and educational institutions.