porcelain 3d printing

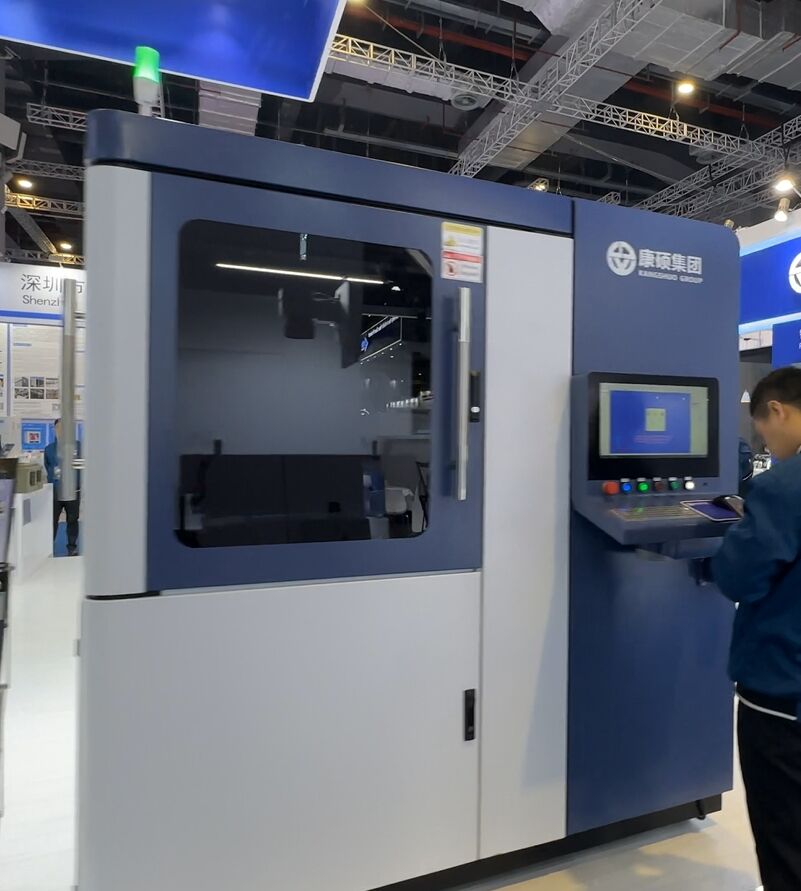

Porcelain 3D printing represents a groundbreaking advancement in ceramic manufacturing technology, combining traditional ceramic craftsmanship with modern digital fabrication methods. This innovative process enables the creation of intricate porcelain objects with unprecedented precision and complexity. The technology utilizes specialized ceramic slurry materials that are carefully formulated to maintain stability during the printing process while ensuring optimal firing results. The printing process involves depositing layers of porcelain material through a precise extrusion system, building objects layer by layer according to digital designs. Once printed, the objects undergo a controlled drying phase before being fired in high-temperature kilns, reaching temperatures up to 1300°C to achieve the characteristic translucency and strength of porcelain. This technology has found applications across various sectors, including fine arts, architectural elements, custom tableware, dental prosthetics, and industrial prototyping. The ability to create complex geometries and internal structures that would be impossible with traditional manufacturing methods has opened new possibilities in design and functionality. Furthermore, the technology supports mass customization while maintaining consistent quality across production runs, making it particularly valuable for both artistic and industrial applications.