steel casting company

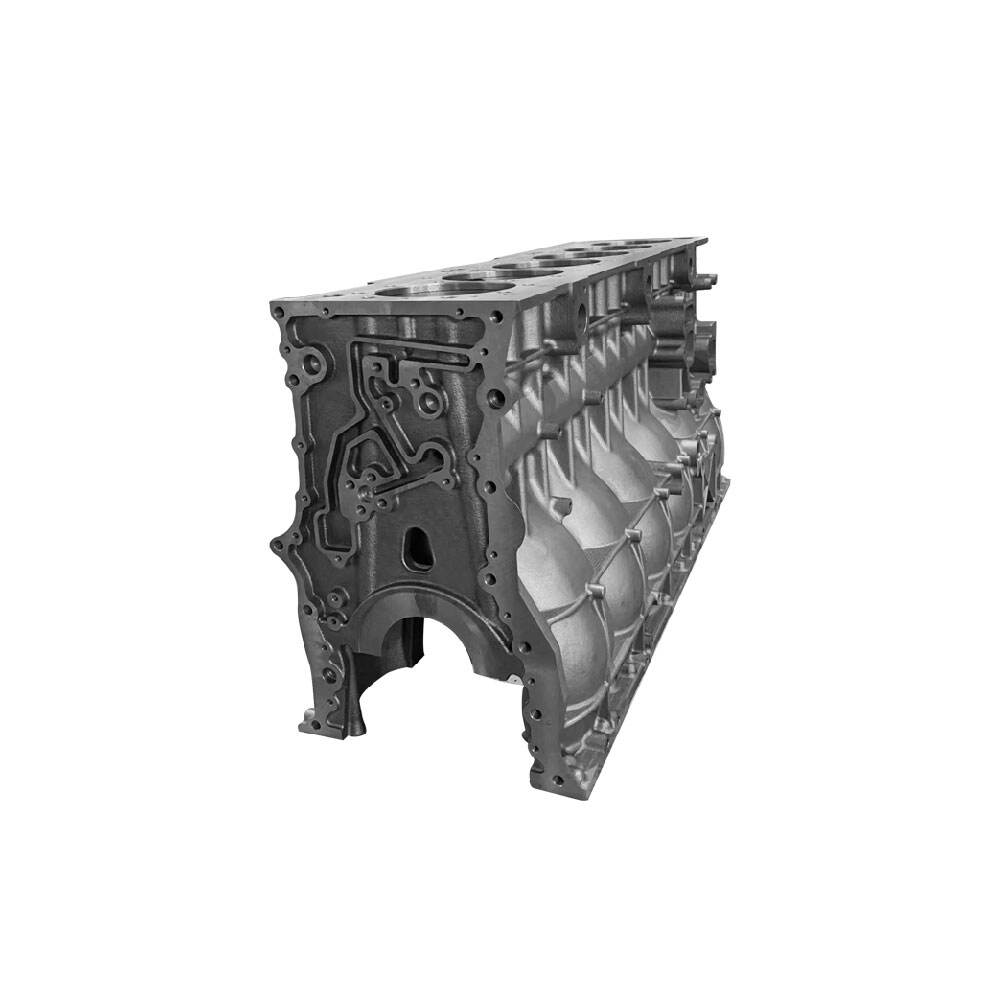

Our steel casting company stands at the forefront of industrial manufacturing, offering comprehensive metal casting solutions that combine traditional expertise with cutting-edge technology. We specialize in producing high-quality steel castings through advanced manufacturing processes, including investment casting, sand casting, and precision machining. Our state-of-the-art facility houses modern equipment capable of handling projects ranging from small components to large industrial castings, with weights varying from a few pounds to several tons. We employ sophisticated quality control measures, including radiographic testing, ultrasonic inspection, and magnetic particle examination, ensuring each product meets strict industry standards. Our technological capabilities extend to computer-aided design and simulation software, allowing us to optimize casting designs and reduce production time while maintaining superior quality. The company serves diverse industries, including automotive, aerospace, mining, construction, and energy sectors, providing custom solutions for complex engineering challenges. Our experienced metallurgists and engineers work closely with clients to select appropriate materials and processes, ensuring optimal performance and longevity of the final products.