aluminium alloy for casting

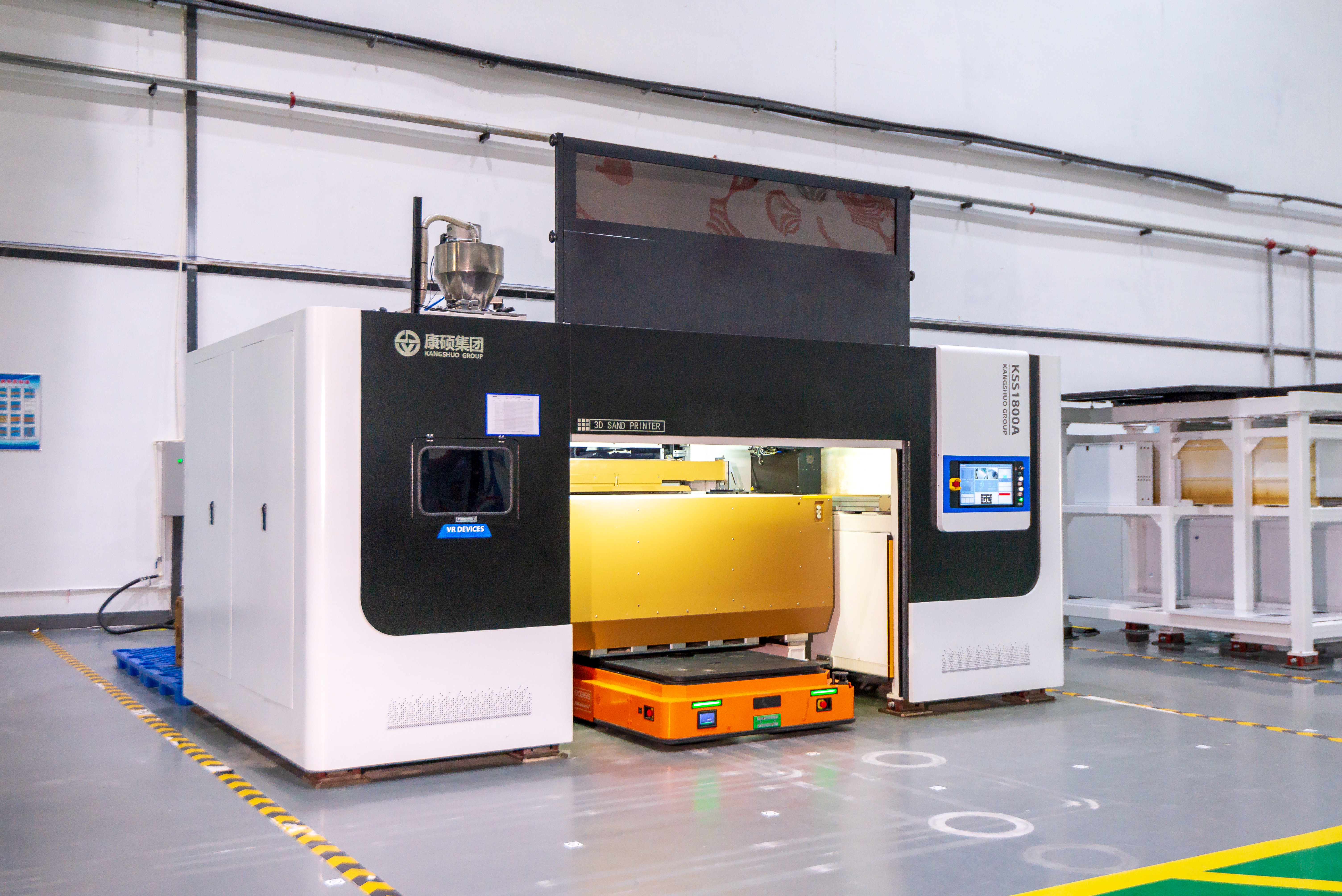

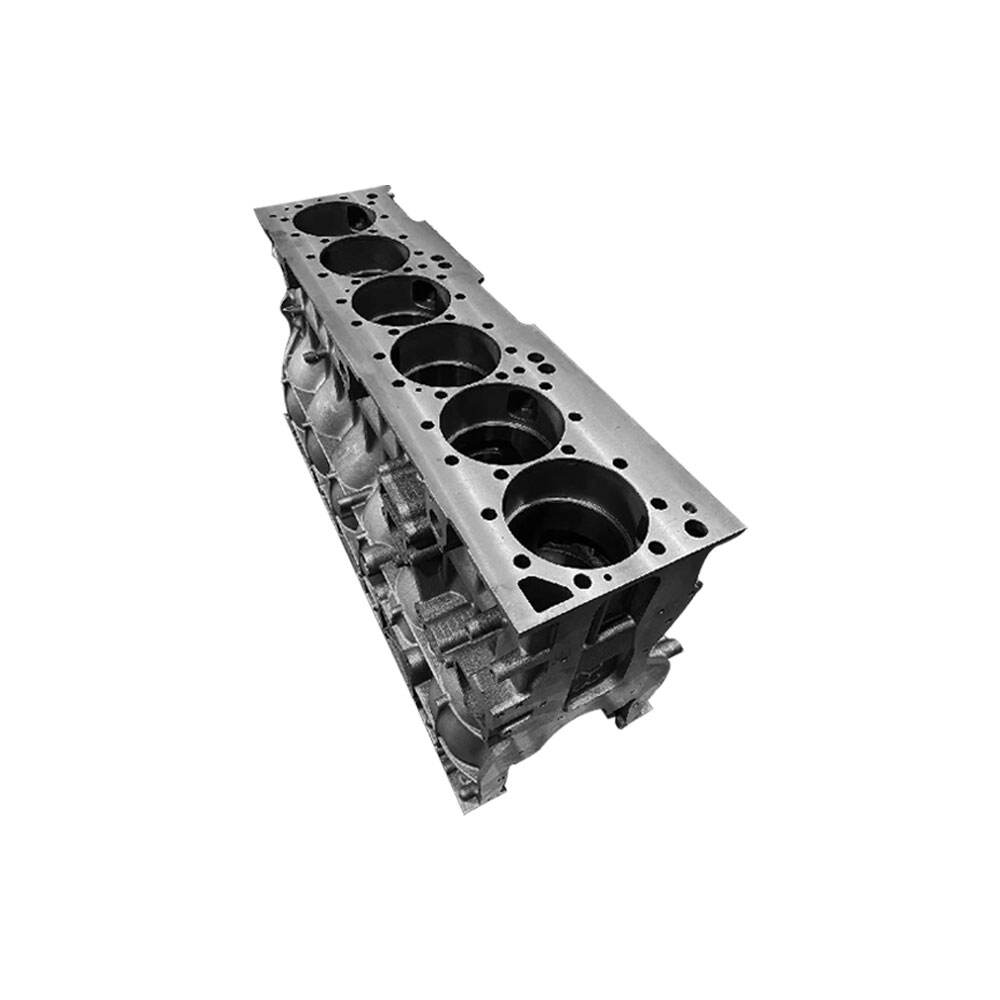

Aluminium alloy for casting represents a versatile and innovative material solution in modern manufacturing. This specialized alloy combines aluminum with carefully selected elements to create a material that offers exceptional castability, durability, and performance characteristics. The alloy's composition is specifically engineered to provide optimal fluidity during the casting process, ensuring precise mold filling and excellent surface finish. Its main functions include providing structural integrity in complex components while maintaining relatively light weight. The technological features of casting aluminum alloys include excellent thermal conductivity, corrosion resistance, and the ability to maintain dimensional stability under varying temperature conditions. These alloys are particularly valued in industries requiring high-performance, lightweight components. Common applications span across automotive manufacturing, where they're used in engine blocks and transmission housings, aerospace components including turbine parts and structural elements, and consumer electronics casings. The material's versatility allows for both thin-wall and thick-section castings, making it suitable for both decorative and structural applications. In marine environments, these alloys demonstrate superior resistance to saltwater corrosion, while in architectural applications, they provide both aesthetic appeal and structural strength.