sand casting near me

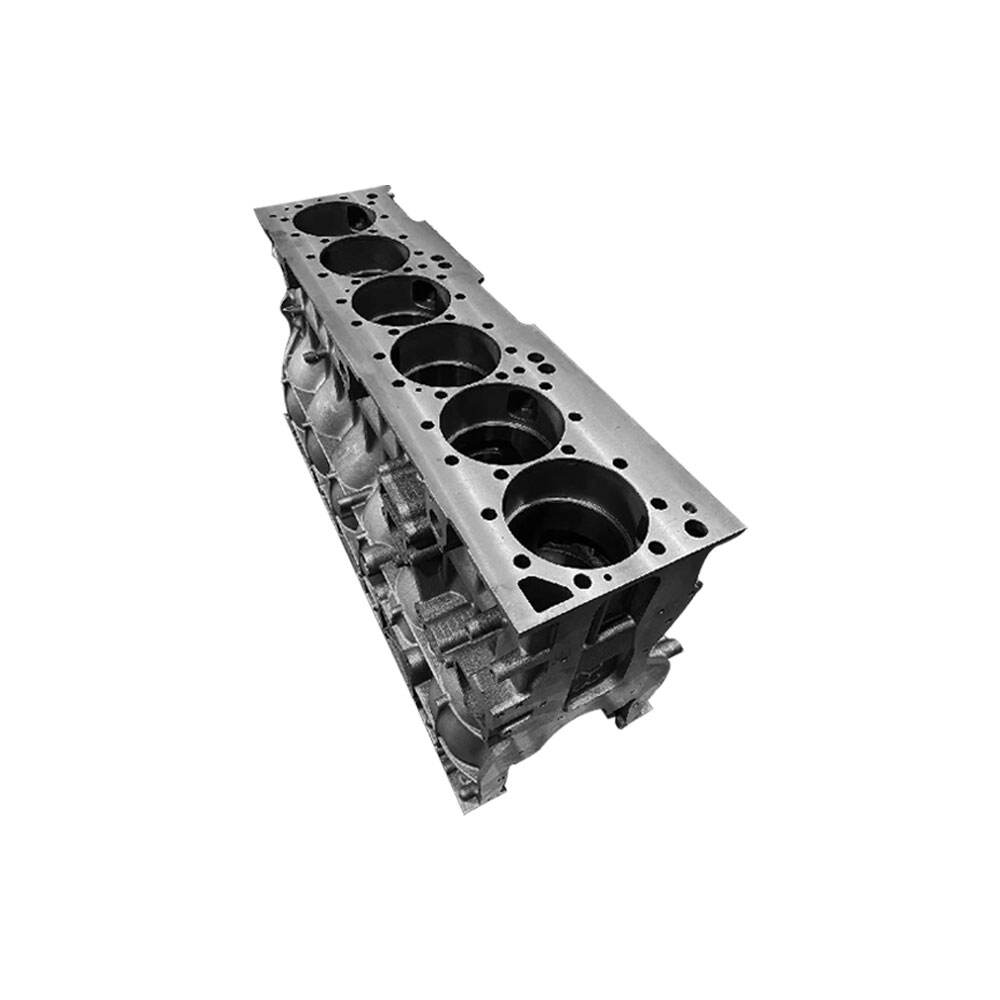

Sand casting near me offers a comprehensive and accessible solution for producing metal components through a time-tested manufacturing process. This versatile method involves creating molds from sand mixtures, allowing for the production of both simple and complex metal parts across various sizes and materials. Local sand casting facilities typically employ advanced equipment and experienced craftsmen who understand the intricacies of pattern making, mold preparation, and metal pouring techniques. These facilities often utilize modern quality control systems and computer-aided design tools to ensure precise specifications and consistent results. The process begins with pattern making, followed by creating sand molds using specialized compounds and binders. Molten metal is then carefully poured into these molds, allowing for the formation of detailed components once cooled and solidified. Local foundries generally maintain capabilities for working with various metals, including aluminum, bronze, iron, and steel, making them valuable resources for industries ranging from automotive to architectural applications. The proximity of these facilities ensures quick turnaround times, reduced shipping costs, and the ability to collaborate closely on project specifications.