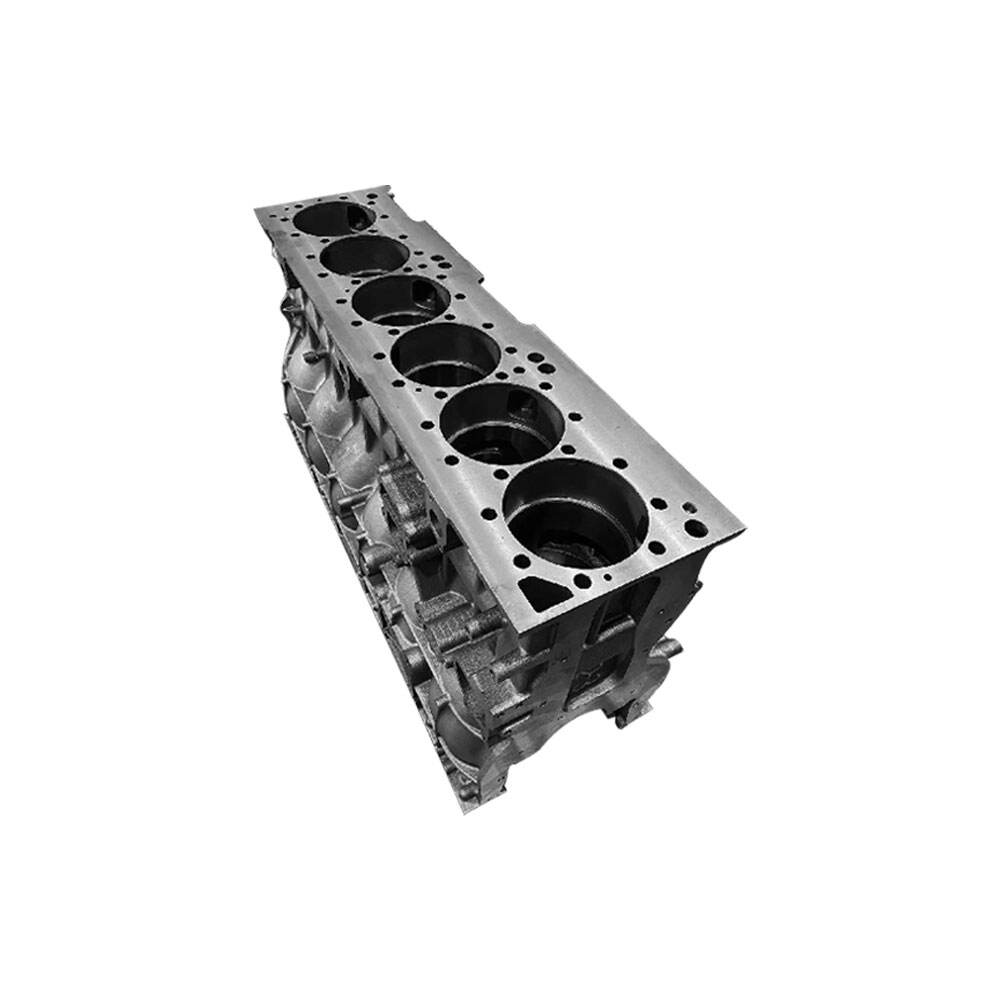

mold sand casting

Mold sand casting is a versatile and time-tested manufacturing process that involves creating metal components by pouring molten metal into a sand mold cavity. This fundamental metalworking technique utilizes specially prepared sand mixtures, typically composed of silica sand, clay binder, and moisture, to form precise molds that can produce complex metal parts. The process begins with creating a pattern that matches the desired final product, followed by packing sand around it to form the mold. The pattern is then removed, leaving a cavity that serves as the template for the final casting. Modern mold sand casting incorporates advanced technologies for sand preparation, mold making, and quality control, enabling manufacturers to produce components with consistent quality and dimensional accuracy. The process accommodates a wide range of metals, including iron, steel, aluminum, and copper alloys, making it suitable for producing everything from small automotive parts to large industrial equipment components. The versatility of sand casting, combined with its cost-effectiveness for both small and large production runs, has maintained its position as a crucial manufacturing method in various industries.