steel casting near me

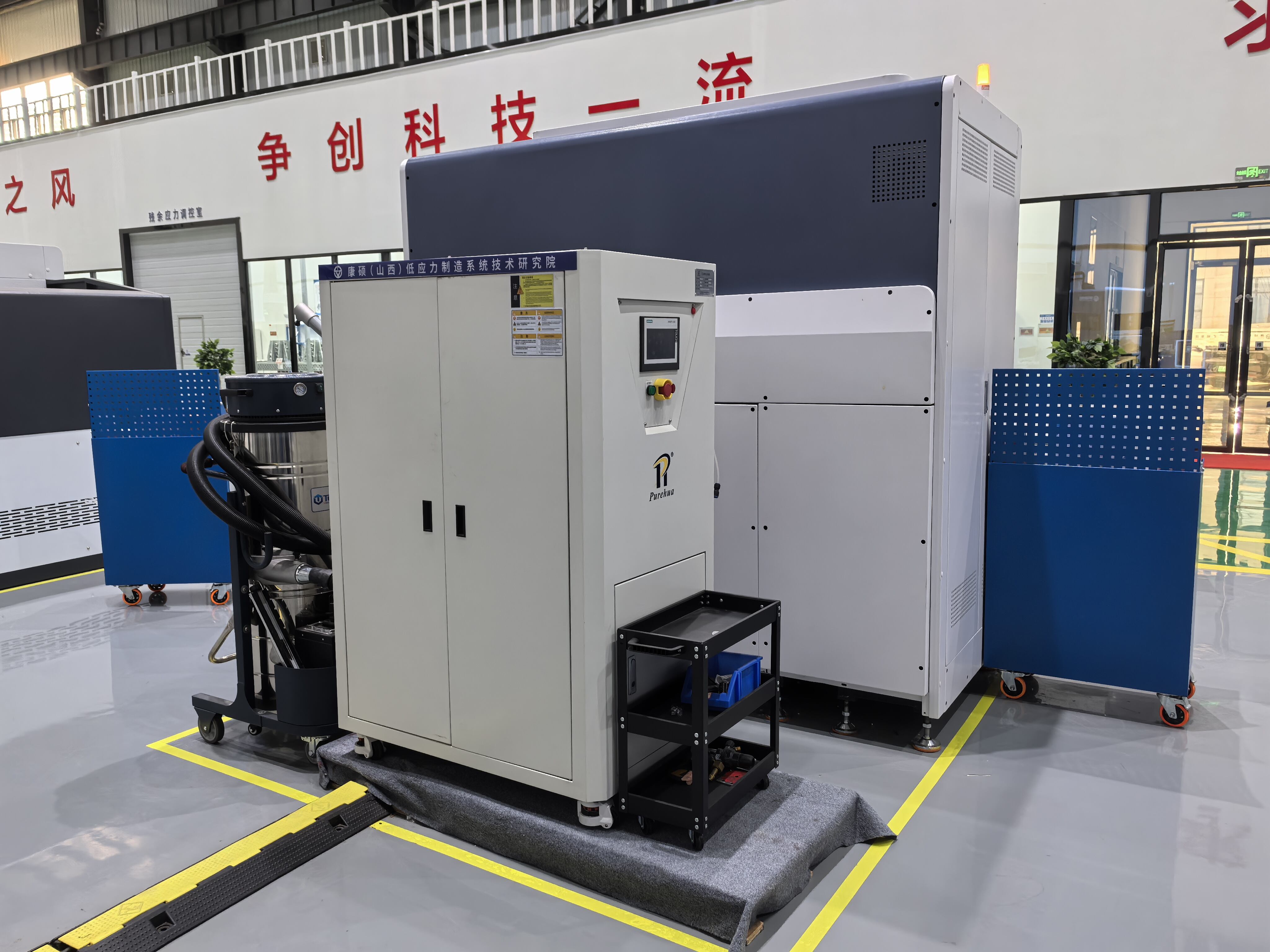

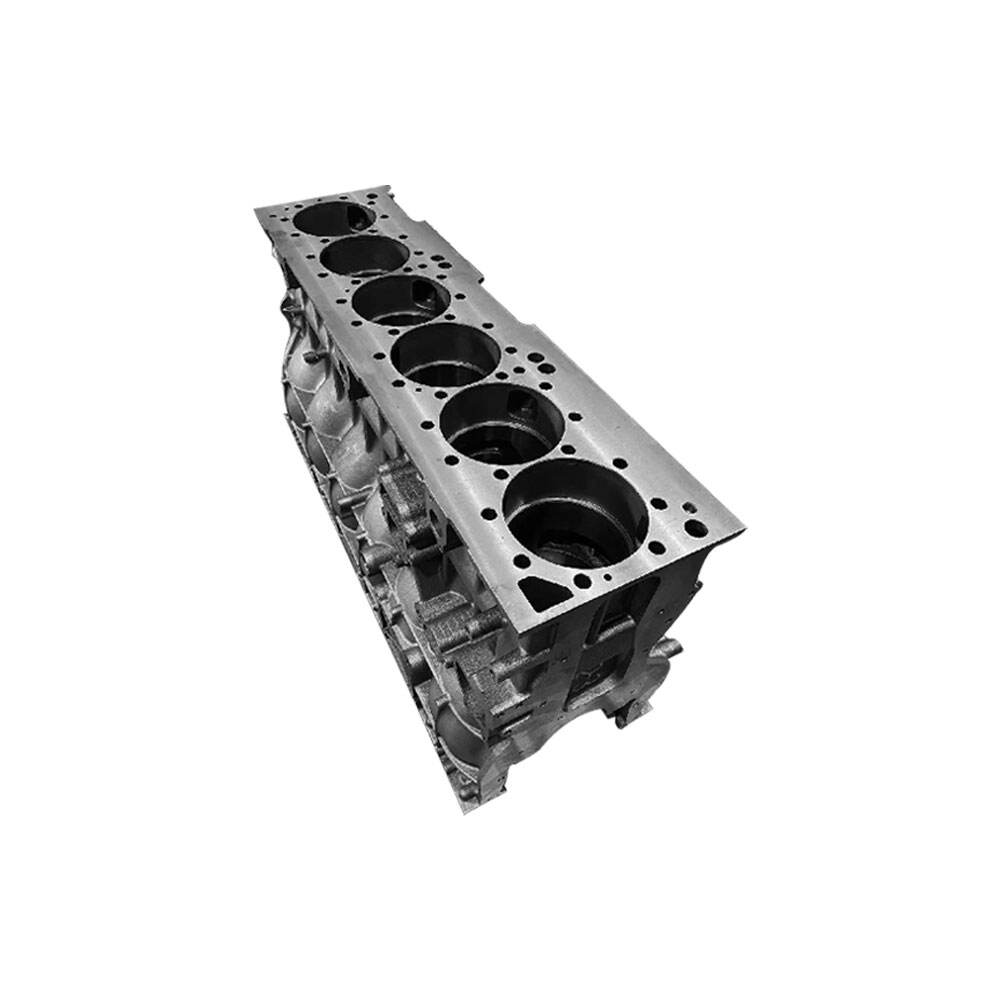

Steel casting facilities in your local area provide essential metal forming services that transform molten steel into precise, durable components. These facilities combine traditional foundry techniques with modern technology to create custom steel parts for various industries. Local steel casting operations typically offer comprehensive services including pattern making, molding, pouring, heat treatment, and finishing processes. The proximity of these facilities ensures quick turnaround times and reduced transportation costs. Modern steel casting facilities employ advanced simulation software to optimize casting designs, reducing defects and ensuring consistent quality. They utilize various casting methods including sand casting, investment casting, and die casting, depending on the specific requirements of each project. These facilities maintain strict quality control measures, following industry standards like ASTM and ISO specifications. The casting process begins with creating detailed molds based on customer specifications, followed by careful material selection and precise temperature control during pouring. Local foundries often specialize in both small batch productions and high-volume orders, offering flexibility to meet diverse customer needs. They typically handle a wide range of steel grades, from carbon steel to specialized alloy steels, enabling them to serve multiple sectors including automotive, construction, mining, and manufacturing.