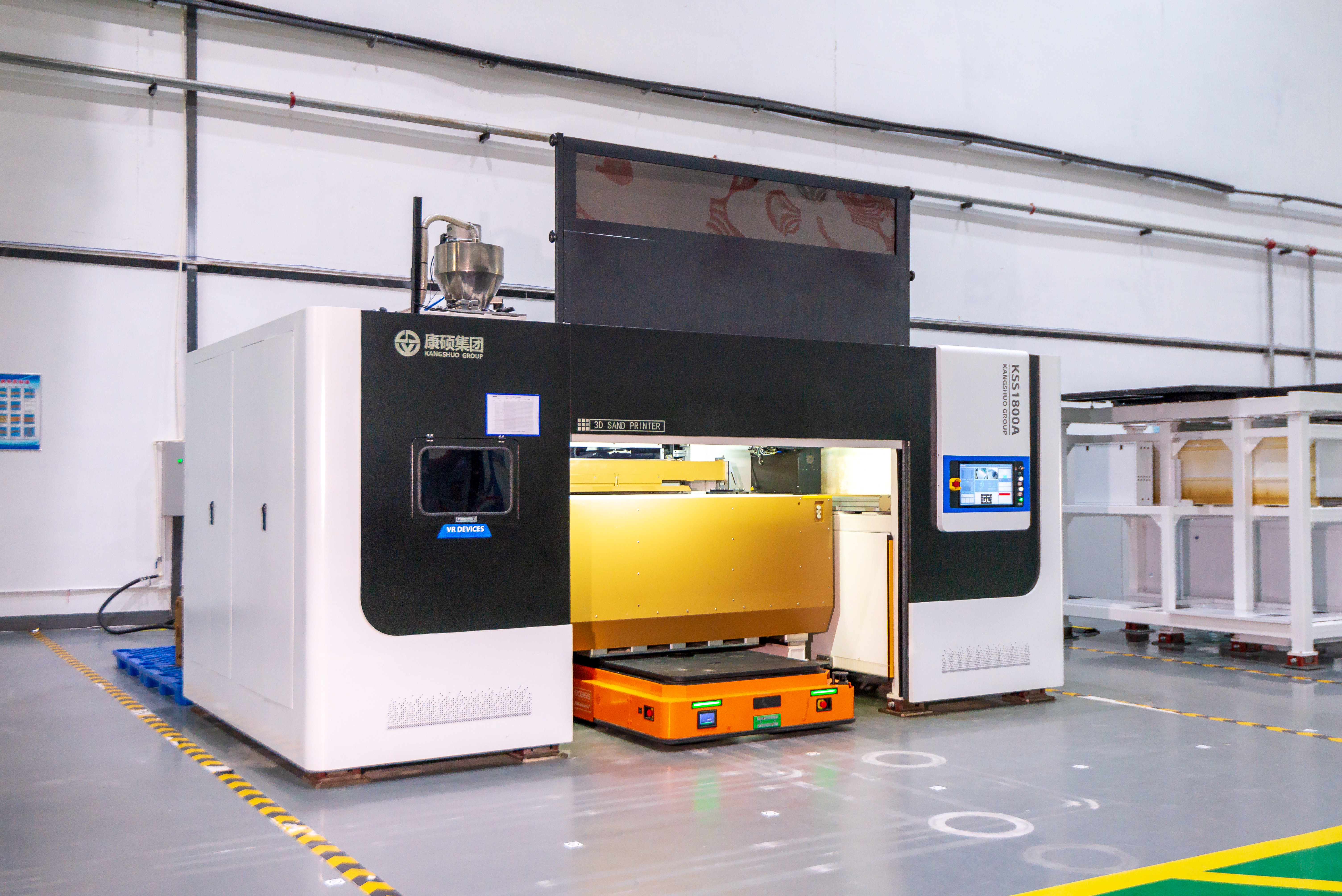

3d sand printer price

The 3D sand printer price represents a significant investment in advanced manufacturing technology, typically ranging from $50,000 to $500,000 depending on the model and capabilities. These machines utilize binder jetting technology to create complex sand molds and cores for metal casting applications. The price variation reflects differences in build volume, printing speed, resolution, and automation features. Entry-level models, suitable for small to medium-sized foundries, generally fall in the lower price range while offering basic functionalities and smaller build volumes. Mid-range printers, priced between $150,000 and $300,000, provide enhanced features such as higher precision, faster printing speeds, and improved material handling systems. Premium models, commanding higher prices, incorporate advanced features like automated post-processing, multiple print heads, and integrated quality control systems. The investment consideration must account for additional costs including installation, training, maintenance, and consumables such as print heads, binders, and specialized sand. Despite the substantial initial investment, these printers offer significant long-term value through reduced tooling costs, faster production cycles, and the ability to create complex geometries impossible with traditional methods.